Manufacturing is not same like before. Earlier people only care if product is working or not. If charger was charging phone, then ok. Nobody asked more.

But today things are different.

People now care how product is made, how strong it is, how safe it feels in hand. Specially in electronics and chargers, small mistake can cause big problem. Crack in plastic, loose body, overheating, all these things customers notice very fast.

This is why injection moulding services for electronics becomes important now. Plastic part of charger is not just cover. It protects PCB, controls heat, gives insulation and also decides how long charger will survive.

Tianyin Worldtech India Pvt Ltd, located in Noida, works with brands who want reliable charger manufacturing. We handle injection moulding as part of overall charger manufacturing, not as separate thing. That helps brands avoid many quality and safety issues later.

In this blog, we are explaining why injection moulding matters in electronics, how it connects with charger manufacturing, and why working with experienced Mobile Charger Manufacturer in India is important for long term success.

The new era of charger manufacturing

Earlier charger manufacturing was simple. Low power, big size, less heat, basic plastic. Nobody talked about design much.

Now charger is totally different product.

Fast charging, higher wattage, compact size, GaN technology, all these things increase power density. More power in small body means more heat. If plastic quality is weak, it will deform, crack or become unsafe.

Today charger manufacturing needs to balance many things:

High power charging

Heat control

Strong plastic housing

Electrical safety

BIS compliance

From basic adapters to intelligent fast chargers, everything now needs proper planning. Plastic injection moulding is not optional anymore. It is part of safety.

Brands who ignore this usually face issues later like product breakage, failed BIS test or customer complaints.

Why businesses need injection moulding services for electronics

Many brands think injection moulding is just plastic shaping. But actually it decides how product behaves in real life.

In electronics, plastic part does many jobs:

Holds PCB firmly

Prevents electric shock

Controls heat flow

Gives strength to charger body

Improves product life

If mould design is poor or plastic material is wrong, charger will not last long. It may heat more, crack near pins, or feel cheap in hand.

This is why businesses prefer working with proper Plastic Injection Moulding Manufacturer India who understands electronics, not only plastic.

For charger brands, injection moulding directly affects:

Product durability

Safety approval

Brand image

Customer trust

When moulding is handled by same company who also manufactures chargers, coordination becomes easier and results are better. This is where OEM manufacturing helps.

How Tianyin Worldtech India Pvt Ltd helps you stand out

Not every manufacturer understands both electronics and injection moulding. Some only focus on PCB, some only on plastic.

Tianyin Worldtech India Pvt Ltd works as integrated manufacturing partner.

We look at charger as complete product, not separate parts. Injection moulding decisions are taken after understanding PCB design, heat generation and BIS requirements.

What we focus on:

Plastic selection suitable for electronics

Mould design that supports heat and strength

Compatibility with charger PCB

BIS safety requirement support

OEM and private label manufacturing

Our team supports brands from early stage till mass production. We don’t rush design. We test, check, improve and then scale.

As charger manufacturer, we use injection moulding services for electronics to increase product reliability, not just appearance.

Key features and manufacturing process

Injection moulding in electronics needs step by step process. Random moulding always creates problems.

At Tianyin, process usually works like this:

Product requirement understanding

We study charger power rating, usage condition, target market and safety requirement.

Mould design and material selection

Plastic material is selected based on heat resistance, insulation and strength. Mould design is done carefully.

Injection moulding for electronics

Precision moulding to maintain shape, thickness and fitting.

Integration with charger assembly

Plastic housing is tested with PCB assembly to ensure no stress or loose fitting.

Testing and validation

Heat test, fit test, safety check before scaling.

Mass production and quality control

Production scaled with same moulding quality.

This allows us to provide Custom OEM Manufacturing Solutions that are reliable and market ready.

Injection moulding and BIS certification for chargers

BIS certification does not check only internal electronics. External body also matters.

Plastic housing affects:

Electrical insulation

Fire resistance

User safety

If plastic quality is poor, charger can fail BIS test even if PCB is fine. That’s why working with BIS Certified Charger Manufacturer is important.

At Tianyin, moulding is done keeping BIS standards in mind. This reduces rejections and saves time for brands.

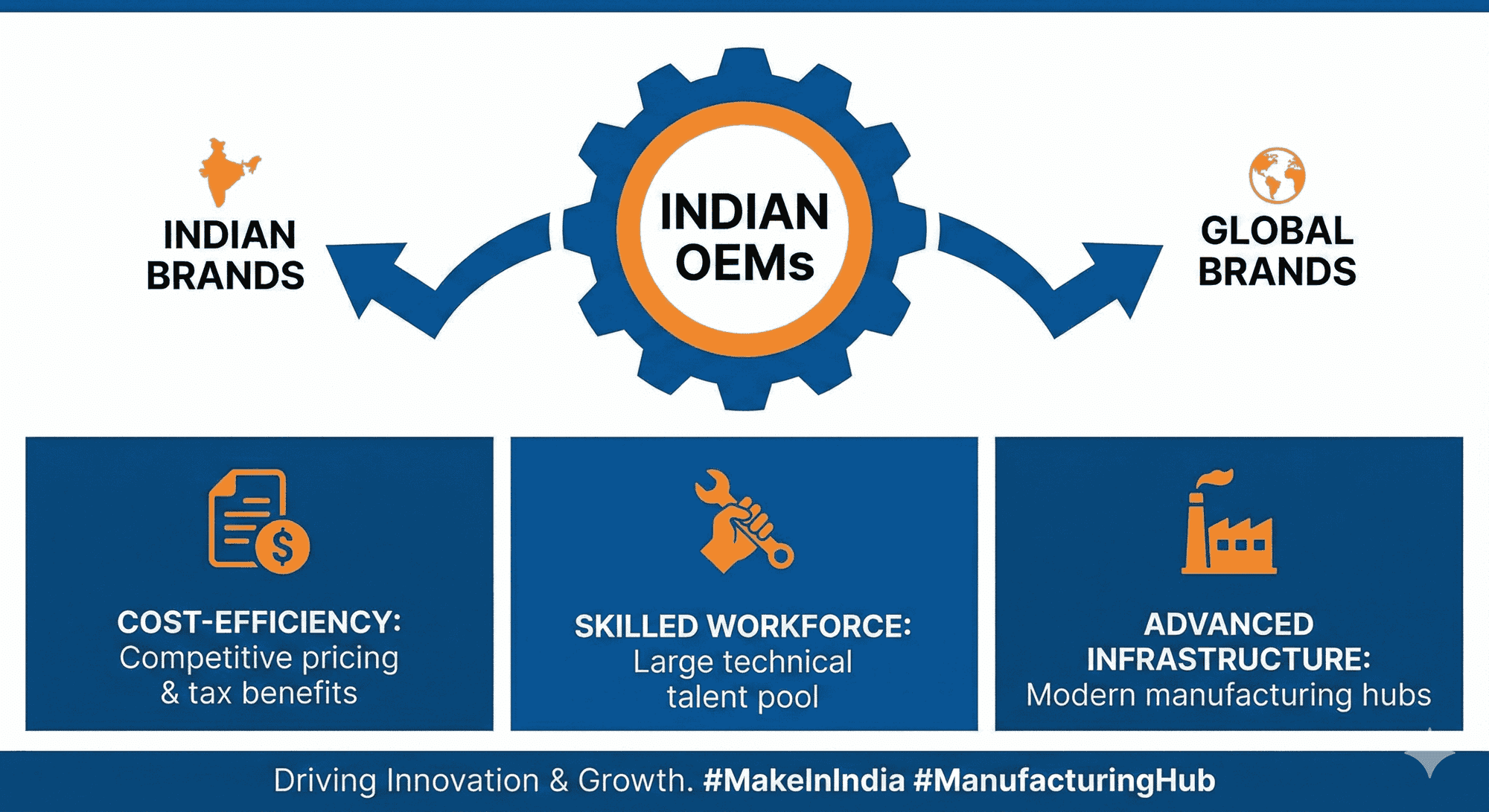

Local manufacturing advantage – Noida

Noida has grown as electronics manufacturing hub in India.

Being based in Noida gives Tianyin many advantages:

Skilled workers available

Easy supply chain access

Faster logistics

Easier coordination between moulding and assembly

Faster design changes

For brands searching Mobile Charger Manufacturer in India, Noida based manufacturing gives speed and control.

Local manufacturing also helps brands monitor production closely and avoid delays.

Client outcomes and real impact

Injection moulding quality shows in real usage.

Brands working with Tianyin usually see:

Fewer cracks and breakage

Better heat resistance

Smooth BIS approval process

Consistent product quality

These results come from experience and proper process, not shortcuts.

The human side of manufacturing

Every charger goes into someone’s home.

Small crack or sharp edge can hurt brand trust badly. Manufacturing is not just machines and numbers. It is responsibility.

Injection moulding for electronics looks simple, but it decides safety and durability. At Tianyin, we take this responsibility seriously.